PRODUCT

![]() HOME > >

HOME > >

Production Cycle

In production process, raw hides are converted into leathers.

UNI CHEM uses the optimized production methods based on up-to-date scientific knowledge on tanning and finishing.

The leathers are also produced with recyclable sources based on UNI CHEM’s original production process.

BEAMHOUSE

The salted leather is soaked into water to reabsorb the water and restore soft and flexible green hide condition. The unnecessary filth, salt, water-soluble protein, etc. on leathers are also removed. After melting out raw hide fur, outer layer, interfiber water soluble protein, and protein with strong alkali chemical, the fibrous tissues are flattened and surface condition are sorted. After that, primary hood is adjusted for a splitting process.

Quality Management

UNI CHEM

Complies to customer needs and environmental laws, through the systemic quality management.

Connects all field data with ERP, through MES and utilizes it for quality management.

Puts it as the priority task to heighten satisfaction about relevant products and services.

To grow as the biggest global leather manufacturer,

all the executive members and staffs of this company understand and implement the quality management system to practice the transparent management system.

Warranty PART

Customer warranty service

Customer business response

Material test PART

Fabric property test

Measurement and test equipment management

Inspections

Automotive leather inspections

Fault inspection Room Management

PART of Quality Management

Textile Shipping Test

Process and Shipping Test, Quality Management

UNI CHEM has a safety and quality management system that constantly monitors and optimizes the safety and quality for production steps.

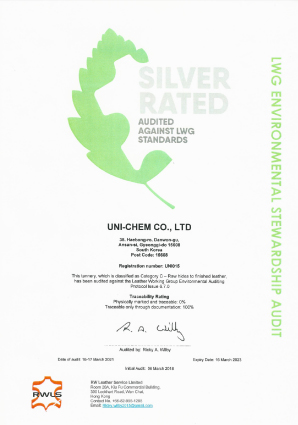

UNI CHEM acquired ISO 9001, IATF 16949, and ISO 14001 LWG SILVER Certificates and all materials and resources comply with test requirements of the international industrial standards.

The in-company process and procurement policy for production, development, and sales fields are part of UNI CHEM’s responsible products and services.

Fashion

UNI CHEM produces high-quality fashion leathers and tries its best to supply satisfactory products.

UNI CHEM is equipped with a system that controls multiple production steps systematically.

UNI CHEM provides the best leathers with outstanding quality, stability, aesthetics, and sustainability based on precise procedure derived by combining advanced technology and traditional leather crafting.

Automotive

UNI CHEM’s leathers comply with eco-friendly production technology and first-grade quality required for automotive interior. The leathers are also specialized for seat cover, steering wheel, door panel, and dashboard.

UNI CHEM produces eco-friendly and chrome-free leathers in excellent quality based on its original technology. UNI CHEM also provides the leathers that match with automotive interior by accentuating the natural fabric’s timeless luxuriousness.

UNI CHEM supports diverse customized projects from concept cars to limited editions and cars that draw new lines for sustainable performance. UNI CHEM also provides finishing applied advanced leather techniques, such as customization, digital punching, digital printing, quilting, embroidery, high-frequency embossing, and welding.

UNI CHEM conducts tests and provides customized color matching service to meet client requests.

Product

Drumdyed

· Item| PIANISSIMO, MIDAS

· THK| 1.2~1.4mm / 1.3~1.5mm

· Characteristics| Touch of Natural Leather, Effect of Naked-Type Lamb Touch, Hand Feel of Sponge Leather Quality

· Use | Dress, Handbags, Purses, Woman Shoes

Soft & Thin

· Item| WAXY NAPPA, SUPEX, ATHENE

· THK| 1.3~1.5mm

· Characteristics| Appropriate for handbags of soft & silky touch, Having elasticity and high-flexibility, Smooth Touch painted with aniline

· Use| Handbags Hand bags, Purses, Dress & Casual Shoes

Full Grain

· Item| TENDER, BBG, F/G

· THK| 1.4~1.6mm / 1.6~1.8mm

· Characteristics| FIRMNESS high quality hand feel, elegant leather quality and LOOKING, various FASHIONABLE COLOR for CASUAL

· Use| CASUAL HANDBAG & SHOE

Shrunken

· Item| NATURAL SHRUNKEN, EMBO SHRUNKEN, DEERCOW

· THK| 1.3~1.5mm / 1.4~1.6mm / 1.6~1.8mm / 1.8~2.0mm

· Characteristics| Natural beauty of SILKEY TOUCH and NATURAL GLOSS, even PEBBLE EFFECT of LIGHT WEIGHT, strength can be adjusted according to customer's request

· Use| HANDBAG & SHOE of various styles

Vegetable Tanned

· Item| ORACLE, CHACO, MUROS

· THK| 1.3~1.4mm / 1.4~1.6mm / 1.6~1.8mm

· Characteristics| Softness, vegetable content, diverse effects depending on milling, elegant looking with vegetable qualities

· Use| HANDBAG & WALLET

Metal Free

· Item| MISO

· THK| 1.2~1.4mm / 1.4~1.6mm

· Characteristics| Eco-friendly and antimicrobial fabric applied with advanced technology, soft and flawless material

· Use| High-quality and high value-added handbag and wallet

Automotive

· Item| CAR-SEAT, HANDLE COVER

· THK| 1.2~1.6mm, 1.0~1.4mm

· Characteristics| Soft, Natural and Automotive leather that meets the SPEC having the property of various matters, Anti-virus, Weight Lightening, Resist Printing, Biodegradable and Eco-friendly Organic Leather

· Use| CAR-SEAT COVERING, STEERING WHEEL